Laser welding is an advanced welding technique that joins metal or thermoplastic components using a focused laser beam. This concentrated heat source ensures high-quality welds, reduced post-processing costs and increased efficiency and productivity.

High-precision laser welding systems meet the requirements of different product assembly specifications, including aerospace, medical, automotive, jewelry-making and manufacturing industries. In addition to high levels of precision, laser welding machines have a range of other benefits that make them ideal across diverse industries.

Explore how laser welding works and the benefits of this technology for a variety of applications.

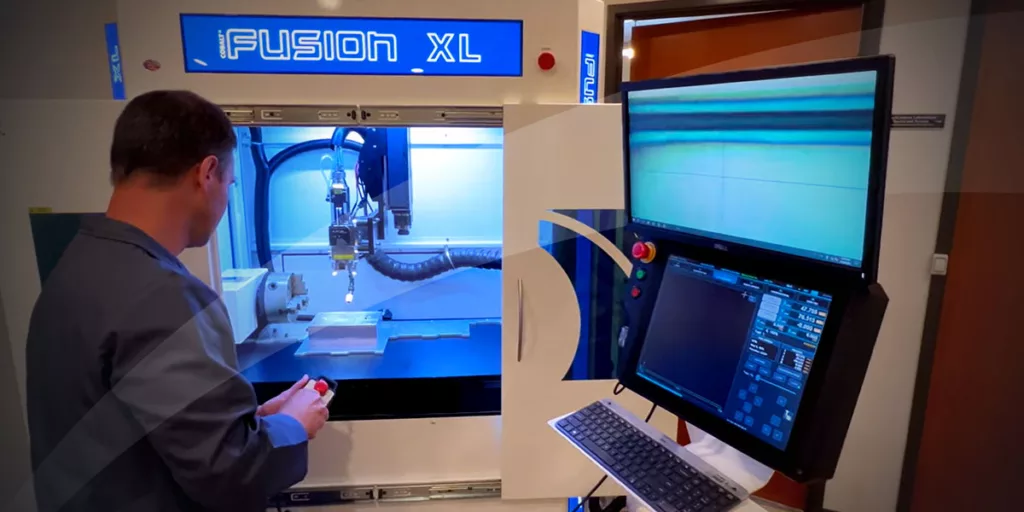

Learn More About The Fusion XL

High-precision laser welding systems produce a concentrated beam of light focused on the cavity between two materials to join them. This process utilizes a Continuous Wave (CW) laser or a pulsed laser to weld materials. The laser moves at high speeds to produce deep and narrow welds.

The hot, powerful laser beam melts the materials at their seams to form a high-quality joint. Laser welding systems give users more control over heat input and welding parameters, such as beam diameter, pulse duration, welding speed and laser power. This reduces the distortion often caused by other welding processes and eliminates post-processing needs.

There are two main types of high-precision welding:

Laser welding systems use a no-contact process to form a strong bond between two metal pieces. They typically produce clean, neat and deeply penetrating seams that are highly sought after in high-precision industries. Other than the nearly perfect seams, laser welding systems have many other benefits.

This type of welding produces highly precise components because the beam typically focuses on a small area. It can also be controlled to satisfy specific parameters, including the beam size, which ensures no cracks, distortions or material damage. The process also produces strong, durable welds that withstand harsh environments and extreme temperatures.

Laser beams have a narrow weld profile that allows you to weld even the thinnest workpieces without damaging them. In addition, laser welding systems prevent material waste and welding errors while ensuring consistent quality in all the workpieces.

Workpieces welded together using a laser are spotless and accurate, eliminating the need for post-processing procedures, such as grinding. As a result, high-precision welding systems are ideal for industries without any tolerance for variations in materials, such as aerospace and medical.

You need well-trained personnel to ensure precise control of the beam and other parameters to produce successful welds.

While the initial investment in laser welding systems is greater than in traditional welding systems, you save more money in the long run due to the fast processing speeds. Faster speeds ensure quicker turnaround and allow for higher production capacities. Laser welding is faster than traditional welding methods because laser beams direct consistent thermal energy at high-speed to the material seams.

The speed is a result of advanced automated technologies like robotics, which increase throughput and allow the systems to run for longer. Additionally, laser welding does not require multiple passes to complete a joint like other techniques. Your joint is complete with a single pass, and you can also weld multiple pieces of metal simultaneously.

With lasers, metal can be welded 50% to 100% faster than traditional methods. Despite the high speeds, laser welding does not result in pockets and voids that would require more time to smooth out. The faster weld speeds and increased levels of automation boost turnaround time and productivity.

Like other welding techniques, laser welding delivers heat to the junction between two metals to melt and form a strong bond between them. A laser beam is different because it only delivers heat to the weld seam. Other methods spread the heat to the surrounding material, resulting in warping, bending, distortion or stress.

The highly concentrated laser beam regulates heat input by transmitting it to a specific width, limiting the amount of heat transmitted to the surrounding material. As a result, the heat-affected zone (HAZ) is minimized, and so is the total heat input of laser welding operations. This reduces the risk of thermal damage and performance loss of the material surrounding the weld seam.

Laser welding allows for the merging of thin materials, from around 1 millimeter to 20 millimeters, depending on the type and power of the laser used. It is a no-contact process that ensures zero physical contact between the welding tool and the workpiece, enabling the welding of tiny and sensitive materials.

Automated laser welding ensures exact alignment and creates clean, narrow seams. The laser beam’s precision also allows you to weld small, delicate parts without the risk of damage or distortion. The suitability of laser welding for small-scale welding applications makes it ideal for various materials, including metals, thermoplastics and other precious and dissimilar materials used in many industries.

Laser Marking Technologies is a leading manufacturer and distributor of laser marking and engraving technologies. We have over 100 years of collective industry experience and utilize the most advanced components on the market to create systems that support numerous industries. Laser technology can help you automate production processes in automotive, aerospace, medical, manufacturing and more.

If you’re looking for industrial laser welding solutions for your business, choose Laser Marking Technologies. We offer competitive pricing, 24/7 support and the best warranties on the market. Request a quote today to learn more about our laser welding systems.