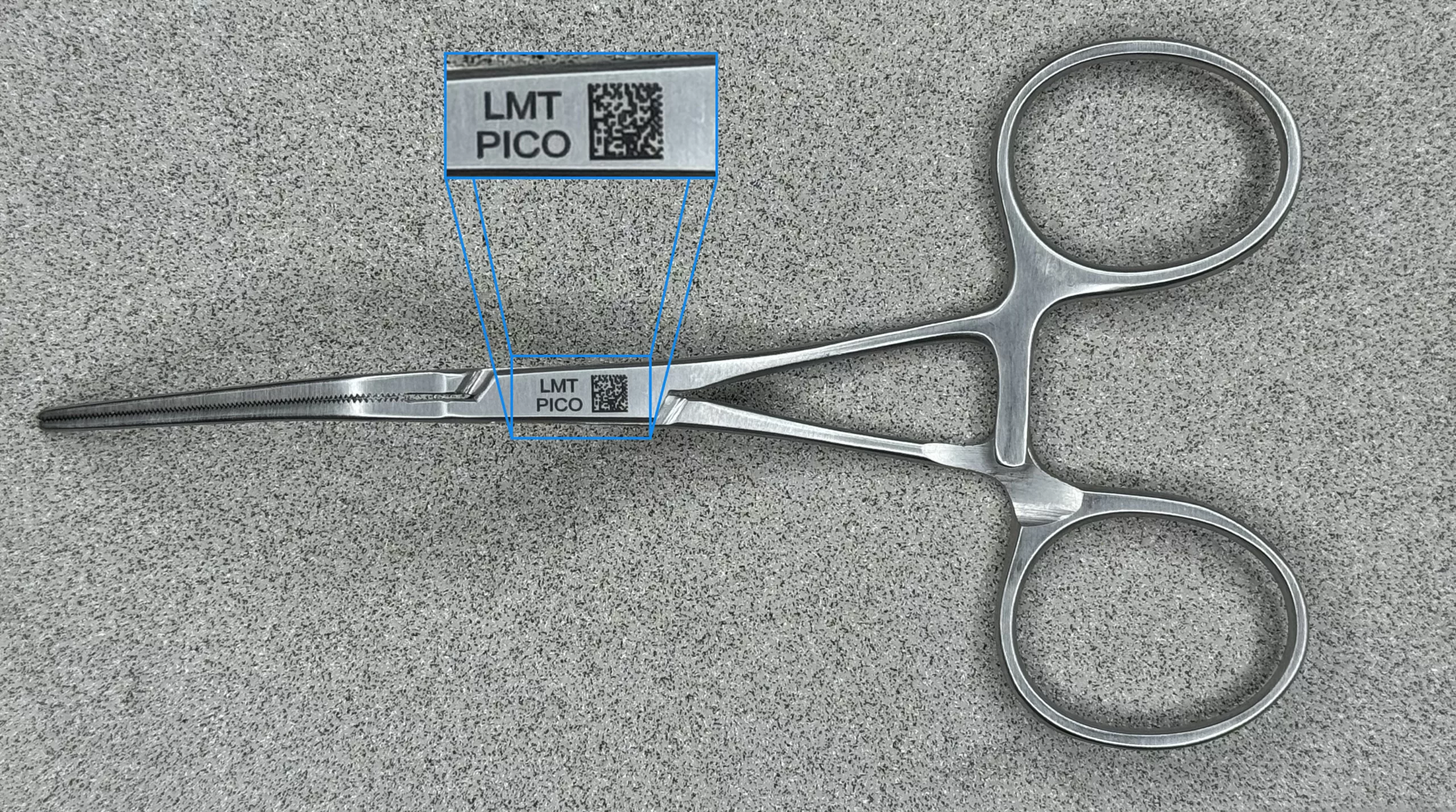

Pico Laser medical device GS1 code

Pico Lasers were initially created for marking within the medical industry. Today, they are used on a large scale, as it guarantees high-quality marking. For medical device manufacturers, the picosecond laser ensures black marking without any reflections. Additionally, laser marking with picosecond withstands citric and nitric passivation cycles.

Click here to learn the process of achieving dark and secure

engravings on medical-grade stainless steel tools.

At Laser Marking Technologies LLC, we harness the power of vision automation with advanced capabilities from industry leaders like Cognex and Keyence. Our systems feature Ethernet connection capability for seamless integration, enabling digital adjustment of positioning and real-time confirmation of proper part selection, loading, and mark completion. With meticulously mounted cameras, our vision automation ensures precision and consistency in every marking operation.

Ensure product quality and traceability with our automation solutions for inspection. Our systems incorporate barcode scanning technology to guarantee readability and integrity of data. Additionally, we offer relative grading for data matrix codes, providing comprehensive inspection capabilities. Through strategically positioned cameras and data matrix mark verification, we empower manufacturers to maintain stringent quality standards.

Streamline your manufacturing workflow with our automation solutions for machine tending. Our UR Ready™ option offers unparalleled flexibility and efficiency, while magazine-fed tag marking systems simplify operations. Experience seamless robot setup and tag slider functionality, enhancing productivity and minimizing downtime in your production environment.

Effortlessly integrate our automation solutions into your existing infrastructure with compatibility across leading PLC systems including Allen Bradley, Siemens, and Modbus. Our TCP-IP communication capability facilitates easy connection into new and established work cells. Navigate through intuitive settings tabs and leverage current IO layout screenshots for seamless integration and configuration.

Experience unparalleled versatility with our automation solutions for motion control. From marking on the fly to gantry marking solutions, conveyor systems, auto doors, and turntables, we offer a diverse range of options to meet your specific requirements. Our solutions are designed to optimize workflow efficiency and adapt to dynamic manufacturing environments seamlessly.

Unlock the power of data-driven insights with our automation solutions for data management. Seamlessly incorporate database integration, including ERP systems such as: Epicore, Oracle, Orchid, and SAP HANA to leverage Industry 4.0 capabilities. Explore comprehensive database views through detailed screenshots, empowering informed decision-making and driving operational excellence.

At Laser Marking Technologies LLC, we are committed to delivering innovative automation solutions that redefine manufacturing efficiency. With our unparalleled expertise and cutting-edge technologies, we empower businesses to achieve new heights of productivity, quality, and competitiveness in today’s dynamic market landscape.

Experience the future of manufacturing with Laser Marking Technologies LLC. Contact us today to learn more about our comprehensive automation solutions and unleash the full potential of your production environment. Let us be your partner in driving success through automation.