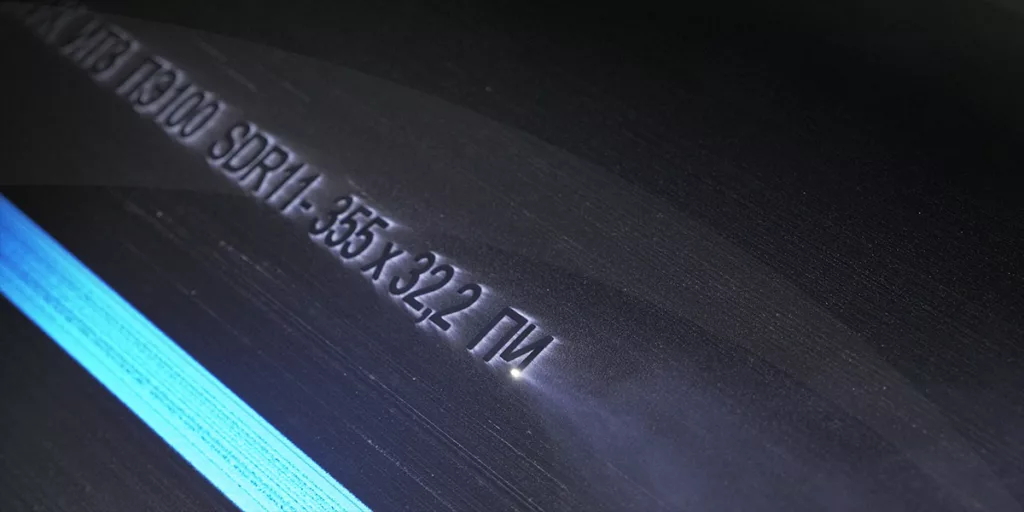

Laser marking is a cost-effective method manufacturers use to create permanent identification marks using a focused beam of light. It can be used to embed various marks, including QR codes, data matrix codes and serial numbers, on various materials ranging from metal and plastic to ceramic.

Laser marking systems require a significant initial investment. However, it provides long-term cost savings since it doesn’t use replenishable inks, dyes and solvents or replaceable tips as in dot peen or scribing equipment. Additionally, you can use one system for all your marking needs, which leads to more cost savings. Learn more about the advantages of laser marking systems.

Automated laser marking systems are a flexible and versatile method that reduces costs in various ways:

Laser marking is a non-contact process that uses a focused laser beam to create precise and concise marks on different materials. This allows manufacturers to reduce costs associated with human error. The high-energy beam is computer-driven and automated to produce consistent results.

With laser marking automation, you can produce high- or low-contrast marks that precisely meet your standards over and over. It also lets you engrave more unique, complex designs that set your products apart in a competitive marketplace. An automated laser produces minimal heat, preventing damage to the surrounding material of the products being marked.

Laser marking systems are faster and more efficient than traditional marking methods. They rely on commands input into automated systems to create markings instead of manual processes or tools that take lots of time to set up. The precise movement of the laser ensures more products or parts can be marked at faster cycle times.

Reducing the time spent with laser marking helps businesses save labor costs and maintain high-volume production. It also enhances efficiency and productivity. The production speed of laser marking systems is, however, affected by several factors, including:

Industrial laser marking systems are long-lasting and durable to prevent frequent replacements. The marks are resistant to wear, fading, degrading and smudging to ensure they remain legible throughout the life span of the marked parts or products. This eliminates the costs of remarking or relabeling the parts or products for a long time.

They can withstand harsh environmental conditions, continual sanitization and washing, rust adhesion paint, and shot blasting. The laser marking systems also boast a long life span with minimal downtime and low maintenance requirements. These systems also help you save costs by not requiring frequent replacements and repairs.

Manufacturers in many industries use laser marking systems to ensure legal compliance with industry standards and regulations. For example, the Food and Drug Administration (FDA) requires all medical equipment and devices to have readable unique device identification (UDI). These identifiers include manufacturing dates, batch numbers and expiration dates embedded in the device body.

The permanent and easily traceable markings ensure easy identification and tracking of equipment parts and components. They also make quality control and accurate documentation easier, preventing product recalls that negatively impact the profits and reputation of a company. Efficient part identification and traceability minimize costs associated with defective materials, counterfeiting and production inefficiencies.

Here are some ways laser marking ensures compliance and traceability in various industries:

Calculating the total laser marking system cost savings involves breaking the costs down and factoring in the time it takes to complete a job. Determining these costs also helps you decide whether it’s worth investing in a laser marking system. The following are real-life examples of how laser marking can save you money.

Laser marking automation significantly reduces the time operators spend working on the markings, significantly reducing labor costs. Here’s the general formula for calculating labor costs:

Let’s assume each operator is paid $22 per hour.

With manual marking, we’ll also assume you need three operators to keep up with your production needs by overseeing machines and operating them to apply marks to your products.

With laser systems, you’ll need less labor to monitor your processes, so only one operator is necessary.

Your total labor cost savings is $44 per hour.

With automated laser marking, you can accomplish tasks in a fraction of the time you would have if you took the manual route.

Let’s assume that our three operators can manually mark 450 units per hour:

With laser systems, you can mark more than three times as many units:

Your total throughput is an additional 1,050 units per hour:

Laser marking systems do not use consumables like dyes, inks, solvents and tool tips, which are typically used with other marking technologies such as printing or chemical etching. The consumables normally increase waste generation and other disposal costs. Here’s a closer look at how laser marking systems reduce waste production:

Since automation reduces human error and waste, we’ll assume that scrapped components decrease from 4% to 0.5%. We’ll also assume that the cost per scrapped component is $40 in waste.

If you’re looking for industry-leading laser marking systems that help you optimize operations and reduce costs, contact Laser Marking Technologies today. We are a reliable laser marking machine supplier of cutting-edge and cost-effective laser marking systems for various applications in many industries, including ablated markings, decorative barrel markings and serial-number annealing.

Our expert team can also help you find the best solution for your unique needs based on your business size and industry. Browse our wide selection of competitively priced laser marking systems with the best warranties.