What Are CO2 Lasers?

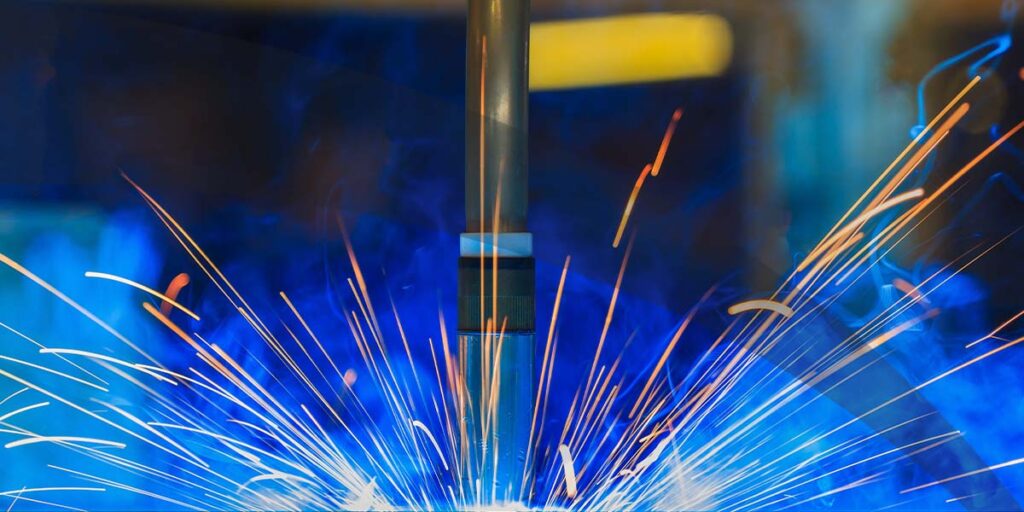

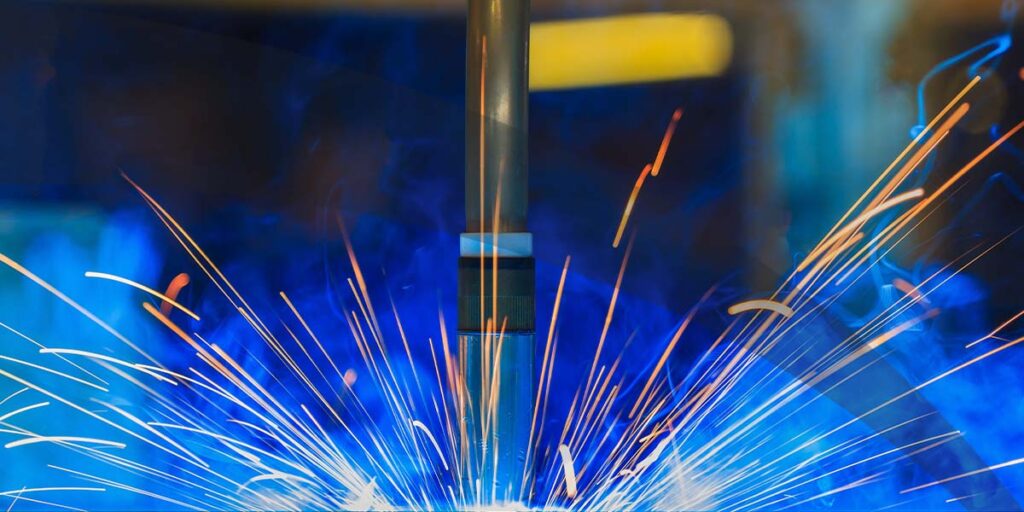

A carbon dioxide laser — or CO2 laser — uses CO2 gas to create a powerful laser beam. These lasers play an important role in manufacturing as they’re used for various welding tasks. If you’re in the market for a CO2 laser system for the first time, you’re probably curious about its unique advantages in weld quality, especially on thicker materials.

Below, you’ll learn more about what CO2 lasers are and explore their material compatibility, features, applications and versatility. You’ll also know what to consider when choosing the right CO2 for your needs.

What Is a CO2 Laser?

CO2 lasers utilize carbon dioxide gas as the laser medium. They work by stimulating a gas mixture containing CO2, helium (He), hydrogen (H2), nitrogen (N2) and xenon (Xe) within a tube using radio frequency waves or a direct current (DC) voltage. This process amplifies light between reflective mirrors, producing a powerful laser beam.

CO2 lasers are widely used in industrial and medical tools because they excel at marking and cutting organic or inorganic materials. However, they are less effective on metals due to their low absorption rates, but they still have engraving capabilities on coated and anodized options.

A CO2 laser wavelength is ten times longer than standard wavelength systems and falls within the infrared range. This long wavelength makes CO2 lasers particularly effective for marking and cutting materials with high absorption rates. A CO2 laser frequency typically operates around 10,600 nanometers (10.6 micrometers).

How Does a CO2 Laser Work?

CO2 lasers typically operate in continuous wave mode, providing a steady output of laser light ideal for cutting and engraving tasks. They come in various models, ranging from low- to high-power systems.

Low-power options range from 10 watts to 400 watts, making them suitable for engraving and marking. High-power options range from 1,000 watts to 6,000 watts, ideal for cutting and welding applications in industrial industries.

These lasers are versatile and flexible, known for their efficient conversion of electrical energy into laser light. Here’s how they typically work:

- Electrodes are positioned within a sealed tube containing a gas mixture to facilitate electrical discharge.

- An electrical current or radio frequency wave is applied to the electrodes, generating a plasma state within the gas mixture and exciting gas molecules.

- The excited gas molecules return to their ground state and emit photons or light particles.

- Photons bounce back and forth between two mirrors at either end of the tube — one fully reflective and the other partially reflective — amplifying the light through stimulated emission.

- The amplified light eventually exits as a coherent laser beam through the partially reflective mirror.

- This beam can be focused for precise cutting or engraving applications using lenses.

- When the laser beam interacts with a piece of material, it generates heat that — depending on the intensity and speed of the laser movement — either cuts through or engraves the surface.

Types of CO2 Lasers

CO2 lasers come in several types, each designed for specific applications and functionalities. Some examples include:

- Transverse flow and longitudinal lasers: These models have simple designs, and they are primarily used for their impressive power output. They continuously vacuum gas via a discharge tube. A DC discharge splits CO2 to create carbon monoxide (CO) and oxygen (O2), which circulates continuously to remove heat loss throughout the system.

- Waveguide lasers: A waveguide featuring a smaller inner diameter replaces the regular sealed tube. The smaller lasing volume produces a lower power output. However, the resonator has a larger surface area than the volume, allowing for efficient heat loss removal.

- Sealed-off lasers: Sealed-off lasers contain glass tubes filled with a gas mixture of CO2, N2 and He. Instead of the pump replacing the gas mixture, H2, O2 and water vapor are added. Since the electrical discharge breaks down carbon dioxide quickly, the water vapor mix is a catalyst to help regenerate the CO2. Mirrors at both ends create a resonant cavity, increasing the operating life.

- High-power diffusion-cooled slab lasers: This laser type has gas between water-cooled planar RF electrodes. Excess heat transfers to the electrodes via diffusion. An unstable resonator supports efficient energy extraction, allowing the laser to produce a large output.

- Transversely excited atmosphere (TEA) lasers: A TEA pressure laser design utilizes a short pulse discharge voltage to prevent arcing. These lasers operate at high pressures with electrodes placed along the tube. TEA models work in only pulsed mode.

- Gas dynamic carbon dioxide lasers: These chemical lasers can have multi-megawatt powers for applications like antimissile weapons. Rather than through gas discharge, chemical reactions provide energy for gas dynamic carbon dioxide lasers.

CO2 Laser Uses & Applications

CO2 lasers have various applications due to their heat-based marking capabilities. They’re fully automated and flexible compared to mechanical cutting tools and have short setup times with fast production runs. Here’s an overview of their uses:

- Cutting applications: CO2 lasers are ideal for cutting glass, plastics, wood and other materials with high absorption rates.

- Welding and coating: Metals like stainless steel and aluminum can be welded and coated with CO2 lasers. Joining two components requires a high temperature for melting without evaporating any material.

- Laser marking: CO2 lasers can mark almost any material, from rubber and glass to wood and cardboard. With laser marking capabilities, you can apply barcodes, logos, serial numbers or artistic applications like engravings.

- Industrial applications: Because of their high precision in laser welding, CO2 lasers are used as cutters for sheets and plates, hardeners for mechanical parts and welding machines in electronics.

- Emerging technologies: Some applications of CO2 lasers extend to polymer 3D laser printing, laser surgery, spectroscopy and remote sensing.

Considerations for Choosing CO2 Lasers

Before selecting a CO2 laser, you should consider the following factors:

- Application: Understand your unique requirements and the materials you plan to use to select the most suitable model.

- Power: Ensure the CO2 laser can work with the type and thickness of the materials you will process. A higher wattage allows for faster cutting and can handle thicker materials.

- Costs: Evaluate your budget for purchasing a CO2 laser system, including any necessary additional equipment and ongoing operational costs such as maintenance, electricity and replacement parts.

- Size: Assess the laser system’s physical dimensions and ensure it fits within your workspace. The size of the working area should also accommodate the largest piece of material you intend to process.

- Manufacturer support: Look for laser manufacturers who provide customer support, warranty options and spare parts. Search for user-friendly systems or ensure training is available for operating the CO2 laser.

Partner With Laser Marking Technologies for Your CO2 Laser Needs

CO2 lasers are important in many modern marking applications. Their versatility makes them appealing as products for various uses, such as cutting and engraving.

Laser Marking Technologies provides state-of-the-art, cost-effective solutions, including CO2 laser systems. We provide tailored solutions based on your specific material processing needs or production volumes and offer flexible financing options to meet your budget. Our comprehensive warranties ensure you’ll enjoy a long service life for the system you procure.

For more information on our products and to learn if CO2 lasers are right for your business, contact our sales team today.