Traditional medical marking methods like stamping and printing can easily lead to damage or counterfeits. The introduction of pico lasers in the medical marking industry is forming new standards for product identification and accuracy.

The United States Food and Drug Administration (FDA) has a unique device identification (UDI) system that stipulates medical devices must be labeled in human and machine-readable form to streamline postmarket surveillance and improve patient safety. Many tools are available to create this, like dot peen marking, but the best option is generally black marking, which has several benefits for medical tools:

Marking medical devices with lasers ensures perfectly visible results with no smudges. Medical staff know the importance of clear markings to prevent patient injury and potential misuse. Even tiny images and text are easy to see with laser markings.

Concentrated laser beams target the areas precisely, creating high-contrast marks that offer high visibility on any surface.

Black marking creates a high-intensity beam that penetrates the top layer of the target material and causes it to increase the temperature, which results in a permanent marking. Laser marking uses vaporization to engrave the target surface beyond the top layer.

Fiber laser technology is nearly impossible to remove since you’d need to cut out a portion of the target material to eliminate it. It also remains untouched during sterilization as it’s not susceptible to even the strongest cleaning agents. Laser marks also don’t corrode over time.

Medical device manufacturers build marking lasers to create as little waste as possible in the healthcare field. Laser marking is one of the most energy-efficient medical tools because it can take as little as a few seconds to label something.

Automated laser marking systems reduce costs because they don’t require any additional resources like ink. By not requiring additional tools and working quickly, lasers lower your carbon footprint as they don’t create unnecessary waste.

This technology was specifically created for the medical industry after being originally developed for the home appliance sectors. Their quality markings make them a necessity in the medical field.

Pico lasers work in short pulses to create highly visible black markings that have no glare or reflections. It keeps the material sterile and doesn’t damage the integrity of tools like catheters.

Compared to other lasers, picosecond markings create a subsurface nonstructural change. In other words, it produces a high-contrast black appearance that’s unaffected by light changes because it traps and absorbs light instead of reflecting it.

Markings made with pico lasers can undergo high temperatures and intense sterilization processes, including centrifugation, which requires a sample to spin at up to 4,000 revolutions per minute (RPM) and could easily remove other types of markings. Pico laser markings maintain integrity even when undergoing destructive testing, such as autoclaving and citric and nitric passivation cycles.

The no-contact pico laser provides a turnkey marking and cutting system that eliminates the stress of errors and product wastage. Its narrow pulse width makes it suitable for almost all medical products, including surgical instruments and implants. It also creates an economical method for marking disposable items like catheters and cannulas.

Picosecond lasers have an ultra-short pulse duration, which allows them to work with fragile materials like glass without shattering. They also create easily visible, matte markings, even on brittle or textured tools.

Picolaser fiber technology has cold ablation, which removes heat transmission from the marking process and prevents accidents with fragile, flammable materials that are prone to heat damage. The reduced peripheral thermal effects allow these machines to remove a higher portion of material with a low input of total laser power. It also promotes multiphoton absorption because the target material is atomized in a cold method instead of being heated to vaporization.

Pico lasers work differently from other options like nanotech lasers. Compared to other marking methods, there are many benefits to utilizing pico lasers in the medical marking industry:

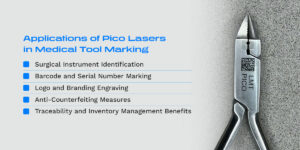

Thanks to their high efficacy, economic benefits and low carbon footprint, picosecond lasers have many applications in medical tool marking. Laser markings improve healthcare instruments’ traceability, making them a popular marking choice in this field.

The laser marking allows healthcare companies to mark each tool with a UDI that meets the FDA standards for identifying medical tools. It’s a durable label that doesn’t corrode and can’t be removed without damaging the surface area of the target material.

Picosecond laser markings are deep black and non-reflective, which enhances visibility for both manual and machine-automated product scanning.

Pico lasers create marks with consistent viewing angles, making them easy to see regardless of reflections or angles. This ensures the brand name and logo remain on the product even over time, which helps with branding. It also aids with locating the product’s origin in the event of a medical emergency.

Pico lasers typically create micro or nano text that’s extremely difficult for counterfeiters to try to create without having access to the original files and a pico laser. The micro text is also typically inconspicuous on the product — only medical professionals can identify them with a scanner.

The reliability of pico laser marking allows for accurate reports and analyses in the case of adverse effects. It improves patient safety by making it easier for healthcare professionals to identify and try to correct potential issues quickly. It also prevents complications with managing device recalls and ensures facilities are prepared for potential medical emergencies.

Laser marking is a permanent and safe method of engraving medical devices without compromising their quality. Our laser marking devices help medical personnel meet the FDA UDI system regulations in an economical and accurate technique.

With over 100 years of collective laser experience, we can help you find exactly what you’re looking for. We have plenty of satisfied customers and look forward to making your laser processes easier and more efficient. If you need assistance finding a pico laser or any other laser marking machine, contact us for advice or check out our demo facilities in an area near you.